Piston or screw, oil-free or oil-lubricated, regulated speed or not, the latest drive technology or a proven principle?

When it comes to purchasing an air compressor or upgrading an existing compressor station plant, you are spoilt for choice. This article gives some brief tips to help you to make a decision. Some good advice to start off with: the selection process should begin with a precise analysis of the compressed air demand and the requirement profile.

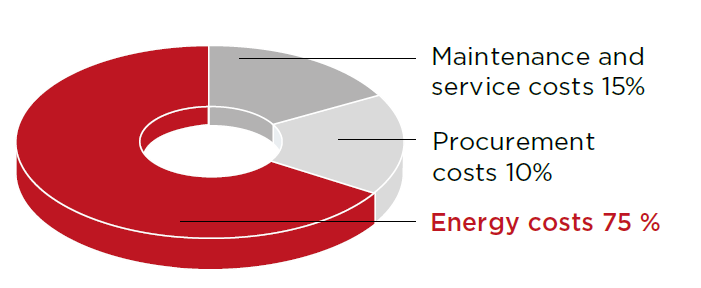

Life cycle costs:

First, a word about comparing the prices of different compressor types and brands: energy accounts for more than two thirds of a compressed air station’s life cycle costs. Therefore, life cycle costs should serve as the benchmark for buying compressed air equipment, not its purchase price. Systems which impress with the lowest sticker price in a tender are not necessarily the most efficient in the long run.

Do your prep: good planning:

Before purchasing a compressor, a range of figures and facts need to be established for the entire compressed air network. These include the compressed air

demand (current and in the foreseeable future), the required compressed air quality and whether the waste heat from the compressor is used for another

operational process. If the compressor is being added to an existing station, then you also need to consider integration into the control technology. It is generally advisable to measure the compressed air demand over a representative period of time and thereby determine a requirement profile for which the compressor or compressors can be selected.

Which operating principle?

The decision regarding the compressor design is best left until later in the selection process. The “Druckluftsysteme für Industrie und Gewerbe” (Compressed air systems for industry and trade) brochure published by the German energy agency (dena) gives a good reason for this: “It is not possible to make a general statement about which compressor is best for compressed air generation. But this is certainly not to say that it does not matter which compressor is selected. Different compressor designs and constructions can result in considerable differences in the associated costs.” In addition, alongside the three “well-known” basic principles of piston, screw and turbo, there are also new operating principles and drive technologies, which were developed with energy efficiency in mind and therefore should be considered and evaluated during

the selection process.

A good tool: Energy Check:

The Energy Check from Gardner Denver has proven to be a good “tool” for determining a user’s current situation and compressed air demand. The Energy Check uses the latest measuring technology and data loggers to record the current state of the compressed air demand along with the load and no-load times of existing compressors over several days. On the basis of these findings, volume flow and performance measurement can be carried out in accordance with ISO 1217 Annex C to provide information about the efficiency of the compressors. These measurements can provide a solid basis for configuring an energyoptimised compressed air station and indicate where modernisation measures are best deployed.

Leakage measurement and elimination:

A comprehensive condition assessment also covers energy consumption and leak measurement. It can often result in considerable savings: even in well maintained compressed air networks, 20 – 30 percent of the generated compressed air can be lost due to leaks, and in some cases it is up to 50 percent. Even a single leak with a diameter of 6.4 millimetres leads to an air loss of 51 litres per second and additional energy costs of almost $3,400 p.a. (Compressed Air Association of Australia) in a seven bar network. The cost of detecting and eliminating leaks normally pays for itself within a few months.

Pressure reduction and heat recovery:

A precise check of the system pressure can also save energy. For example, is 8 bar really needed, or would 7 bar suffice? If it would, then you would save eight to ten percent of the energy costs relating to compressed air – without any investment. Heat recovery can also considerably raise the efficiency of the compressor station, as there are many thermal processes where the waste heat can be used. In the case of oil-injected compressors, 94 percent of the energy used can be recovered as heat.

A focus on compressed air quality:

These days, it is essential to take new developments and findings into account when deciding which technology will best generate the required compressed air quality. High-tech, cutting edge compressors for generating oil-free compressed air and refined traditional piston compressors both play important roles here. This is particularly true for sensitive production processes, where at least part of the compressed air flow must meet the highest quality requirements. It may be used, for example, as sterile air for ventilating fermenters in the pharmaceutical industry or food production, for filling and packing lines or electronics manufacturing and paint shops. In these cases, as a processing medium the compressed air must be 100% oil-free, which poses the question of whether to generate oil-free air directly or by filtering. This has been a highly controversial debate in the past. While removal of the oil aerosols from the compressed air is a complex process, compression in an oil-lubricated compressor is, to date, considered more efficient.

Modernisation pays off:

With running costs accounting for more than two thirds of a compressed air system’s life cycle costs, modernisation – even with high investments in advanced energy-saving compressor technology – typically results in lower costs than continuing operation with a suboptimal system. This means that the energy consumption of a compressor station is the decisive cost factor. A higher initial investment can result in a rapid return on investment. Take the following example: I think this should be compared to a suboptimal solution to show that it has a fast payback period.

Summary: Impartial planning:

It is best to approach planning without preconceived opinions such as “it has to be a screw compressor/ piston compressor/oil-lubricated compressor” or “we need a 30 kW machine.” It is better to carefully Consider all the options. If you consult specialists, they should also not be tied down to one specific compressor type. A precise analysis of the current situation and calculation of the current compressed air demand and pressure level, along with that expected in the future, should always be used as the basis for your decisions. If the system components, including those for treatment, are integrated and maintenance expenses have been determined, then running costs – of which energy costs are a significant proportion – can be estimated with a great deal of accuracy.